Frequently Asked Questions about our technology and our products

Hereafter you can find some of the most common questions about nitrogen and oxygen generators. Click on the question of your interest and you will be routed directly to the relevant answer. Please contact us in case you need additional information.

- How does the PSA air separation process work?

- How does the membrane air separation process work?

- Is a PSA Nitrogen Generator better than a Membrane Nitrogen Generator?

- Is it necessary to change the molecular sieve of PSA nitrogen and oxygen generators?

- What are the specific benefits of the PSA nitrogen and oxygen generators from IGS?

- Why is the nitrogen purity expressed in residual oxygen content?

- What is the difference between a chemical (galvanic) oxygen measuring sensor and a zirconium oxide measuring sensor?

- How reliable are purity measurements of 10 or less ppm of residual oxygen?

- What does a full PSA nitrogen or oxygen system installation require?

- What is the influence of the ambient conditions at the installation site?

- What do design ambient temperature and operating ambient temperature exactly mean?

- Why do I need an air dryer?

- Can I use air compressors with an integrated air dryer?

- Is the application of a desiccant drier better than a refrigeration drier?

- What is the purpose of the gas receiver tank?

- Do I really need a Touch Panel?

- What is the power supply requirement?

- What is the maintenance cost of an IGS gas generation system?

- I don't find my nitrogen or oxygen application on the Application pages. What should I do?

- Do you have a referral/reference list?

- Is there an installation site I can visit?

- Do you offer installation service?

- Do you offer startup service?

- How does the PSA air separation process work?

See our PSA page.

- How does the membrane air separation process work?

See our Membrane page under "Technology & Engineering".

- Is a PSA Nitrogen Generator better than a Membrane Nitrogen Generator?

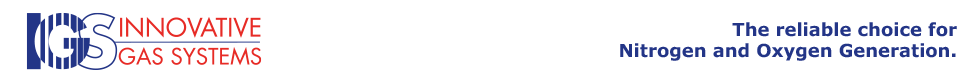

For many nitrogen applications absolutely not. Some suppliers make you believe that a PSA generator is the best solution, because they simply cannot offer you an efficient membrane technology. That's the difference compared to IGS. Besides our patent pending PSA technology, IGS is also one of the world's largest suppliers of hollow fiber membrane modules for air dehydration and nitrogen production. Our GENERON IGS membrane modules set market standards in terms of efficiency and productivity. Having both technologies in house, we will offer you the most suitable solution for your specific nitrogen application:

- Is it necessary to change the molecular sieve of PSA nitrogen and oxygen generators?

Incorrect designed PSA generators from other manufacturers and/or the use of low-quality molecular sieves with insufficient strength do indeed need a regular renewal of their molecular sieve. Fortunately, the PSA generators from IGS don't require such major and very inconvenient overhauls.

As long as the feed air is of sufficient quality, the PSA generators from IGS do not need any renewal of the molecular sieve during their entire lifetime. IGS verifies every new design with extensive CFD calculations and running tests before market introduction to assure low gas speeds through the molecular sieve beds and maximum durability. IGS applies exclusively first-class quality molecular sieves for all its PSA nitrogen and oxygen generators.

- What are the specific benefits of the PSA nitrogen and oxygen generators from IGS?

Besides the general advantages of on-site gas generators, like an economical and just-in-time gas production without risk for gas price increases, the NITROSWING and OXYSWING PSA nitrogen and oxygen generators from IGS offer you the following unique additional advantages:

Reliable: Small or large generators, all our products are designed to be operated on a 24/7/365 basis. Simple operation, stable gas purity, minimum maintenance costs and a maximum system availability insure maximum customer satisfaction.

Flexible: The modular NITROSWING and OXYSWING PSA nitrogen and oxygen generators are the only truly flexible gas generators on the market. Our patent pending design allows you to adapt your system to changed gas supply requirements at any time simply by adding modules or by installing a so-called dual-bank in parallel. This easy modification can be done locally at the installation side without the need for special trained technicians.

Safe: The PSA towers/modules of all our generators are thoroughly calculated and tested for fatigue cracking and have a mathematical infinite life time. No risks for your personnel, no need for renewal of your pressure vessel approval.

Efficient: Extensive CFD flow simulations have resulted in a maximum utilization of the molecular sieve bed. Additionally the pressure drop over the bed has been kept minimal in order to supply you highest gas discharge pressures without the need for expensive gas boosters. The NITROSWING and OXYSWING PSA nitrogen and oxygen generators from IGS produce more gas with less air than anybody else. And that you will notice in your monthly energy bill.

- Why is the nitrogen purity expressed in residual oxygen content?

Non-cryogenic air separation processes by PSA and hollow fiber membranes do not produce pure nitrogen, but an inert gas, which mainly contains nitrogen, but includes also some other inert (noble) gases, like argon. Expressing the purity of this inert gas in amount of residual oxygen means simply saying how things really are.

- What is the difference between a chemical (galvanic) oxygen measuring sensor and a zirconium oxide measuring sensor?

The measuring principle of chemical or galvanic oxygen sensors is based on a chemical reaction where the measuring sensor itself gets consumed. In order to guarantee reliable and stable oxygen measurements, such sensors have to be replaced every 6 to 12 months, even when your oxygen of nitrogen generator is not operated (the sensor reacts with the oxygen in the ambient air). After such periods the oxygen measurement by chemical or galvanic oxygen sensors becomes meaningless, which is very dangerous for critical nitrogen and oxygen applications.

IGS applies as standard zirconium-oxide oxygen measuring sensors, which have a stable and reliable oxygen measurement for a period of five years at least and do not get consumed when the generator is not operated.

- How reliable are purity measurements of 10 or less ppm of residual oxygen?

Unfortunately there are suppliers in the market who "help" the numbers to have this purity displayed on their generator's control panel, but in reality the produced nitrogen contains 50 or even more ppm of residual oxygen. Many nitrogen applications do not require such high nitrogen purities, so most customers will not notice that they do not get for what they paid for.

If a nitrogen generator is supposed to produce such a high purity, but it is offered with the same residual oxygen analyzer as for lower nitrogen purities, you should become suspicious. Standard applied galvanic and zirconium oxide measuring cells for the other purity levels cannot measure such low oxygen concentrations and will indicate far lower values than the real oxygen presence in the produced nitrogen.

IGS stands for reliability and trust. Therefore we offer for such high nitrogen purities a special residual oxygen analyzer with a proper measuring range for a reliable measurement of residual oxygen concentrations between 0 to 20 ppmV.

- What does a full PSA nitrogen or oxygen system installation require?

Our typical system is composed of a NITROSWING or OXYSWING PSA generator and a gas receiver tank. The complete operating system also requires a feed air compressor, an air dryer and air-receiving tank. While IGS does not manufacture air compressors, dryers or tanks, we offer them as part of the system package.

- What is the influence of the ambient conditions at the installation site?

The ambient conditions at the installation site have a very important impact on the performance of a PSA generator:

- Higher ambient temperatures = higher feed air temperatures;

- Gases expand with higher temperatures, so less feed air mass can be loaded into the PSA adsorber tower during each cycle, as tower volume and adsorption pressure remain constant;

- The adsorption efficiency of any molecular sieve for non-cryogenic air separation (also those applied by other PSA generator manufacturers) decreases with increasing adsorption temperatures;

- The size of the air compressor for a PSA generator has to be factored for site elevation. Higher elevations will require a larger air compressor;

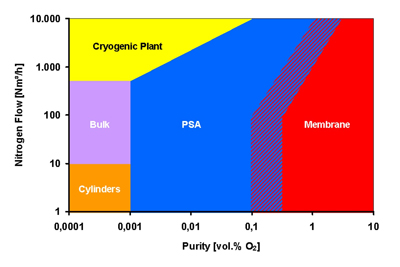

So the produced mass flow of the PSA oxygen or nitrogen generator (expressed in Nm3/h) strongly depends on the actual ambient temperature at the installation site, as can be seen in the following graph:

Assumption: 65% Relative Humidity for all ambient temperatures, installation site at sea level.

As can be observed, the product mass flow of any PSA nitrogen or oxygen generator, and independent from its manufacturer, decreases at increasing ambient temperatures. But the feed air consumption expressed in the generally applied performance unit for air compressors, m3/min FAD (Free Air Delivery) at ambient temperature, remains constant or even increases, which is very important to know for the selection of the right air compressor. And this situation even deteriorates at higher relative humidity values!

The consideration of this behavior during the dimensioning of a PSA system is essential, not only to select the correct PSA generator, but also to select a feed air compressor with sufficient capacity. We want to supply you a system that always works. That's why we need to know the altitude and the highest ambient temperature and corresponding relative humidity value at your installation site in order to supply you a correctly dimensioned PSA system, which is able to supply your gas requirements even under the toughest conditions. See also following answer to Question No. 11 for additional information.

- Higher ambient temperatures = higher feed air temperatures;

- What do design ambient temperature and operating ambient temperature exactly mean?

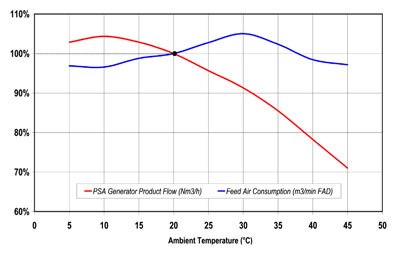

The design ambient temperature is the temperature for which the performance data of the PSA nitrogen or oxygen generator is valid. For example, the design ambient temperature for the PSA system of the performance graph of previous Question No. 10 is 20 °C. At this ambient temperature the performance of the PSA system is identical to the written performance data, but the performance changes at different ambient temperature values, as can be seen in the same graph.

The operating temperature range includes all ambient temperatures at which the PSA nitrogen or oxygen system can be operated. In the before mentioned graph of Question No. 8, the operating ambient temperature range is between +5 °C and +45 °C. But the performance of the PSA system changes significantly over the entire operating temperature range!

No here comes the trick many manufacturers apply when they offer you a PSA system and which you should be aware of very carefully:

Making a lot of confusion about design and operating ambient temperatures in their quotations

so that you believe that the proposed PSA system has a constant performance over the entire operating range. But this is physically impossible!

As above graphs shows you, the size of the PSA generator should be increased by 29% in order to have the same mass flow at 45 °C as at the previous design ambient temperature of 20 °C. However, in both situations the operating temperature range is equal!

The following table shows you an example of the different approach from IGS:

IGS Competition Design Temperature 45 °C (specified in offer) 20 °C (often not specified in offer) Operating Range + 5 °C - +45 °C + 5 °C - +45 °C PSA Product Flow @ 20 °C 129% of Requested Flow Rate 100% of Requested Flow Rate PSA Product Flow @ 45 °C 100% of Requested Flow Rate 71% of Requested Flow Rate

Conclusion: High risk for insufficient gas supply to your application at high ambient temperatures!

- Why do I need an air dryer?

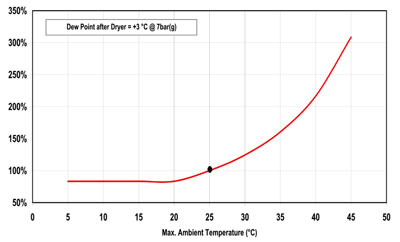

An air dryer assures that air is supplied at the proper dew point for the ultimate generator performance. However, like the PSA generator and air compressor, the air dryer has to be selected for the highest ambient temperature at the installation site in order to avoid that feed air with too high water content is getting to the molecular sieve:

The above graph clearly shows you that the air dryer capacity at a maximum ambient temperature at the installation site of 35 °C should be 50% higher than the requested capacity at 25 °C and at 45 °C you need an air dryer with a capacity which is even three (!) times larger than the dryer capacity at 25 °C.

Too small dimensioned air dryers = irreversible damage of the molecular sieve on the long term!

- Can I use air compressors with an integrated air dryer?

Only if the ambient air temperature at the installation site does not exceed 25 °C / 77 F. As explained with Question No. 12, the drying capacity of an air drier strongly depends on the ambient temperature and the incoming feed air temperature. Integrated driers have an insufficient capacity at ambient temperatures above 25 °C / 77 F and therefore the installation of a specifically sized separate air drier will be required to guarantee the proper dew point for the ultimate generator performance.

- Is the application of a desiccant drier better than a refrigeration drier?

Certainly not at ambient temperatures above 25 °C / 77 F. The compressed air from the air compressor normally has a temperature which is 10 to 15 °C above ambient temperature. An correct sized refrigeration drier not only guarantees a sufficient dew point of the feed air to the gas generator, but will also cool the feed air. Feed air cooling has two important beneficial effects:

-

Your nitrogen or oxygen generator will have a higher gas production at a better efficiency;

- The molecular sieve of your nitrogen or oxygen generator will not be exposed to too high operational temperatures and thus ensuring a longer lifetime of the same.

-

Your nitrogen or oxygen generator will have a higher gas production at a better efficiency;

- What is the purpose of the gas receiver tank?

The gas receiver tank allows the gas to be delivered to your application at a consistent flow rate and a consistent pressure. The size of the tank has little influence on the average discharge pressure of the produced nitrogen or oxygen, but smaller tanks increase the pressure fluctuations during the PSA cycles.

IGS offers slightly larger gas receiver tanks than other manufacturers in order to guarantee a constant gas discharge pressure with no fluctuations.

- Do I really need a Touch Panel?

IGS does offer Touch Panels as option for the HMI (Human Machine Interface) of its OXYSWING® and NITROSWING® modular PSA generators. However, touch panels are more sensitive to extreme ambient conditions with the risk that the LCD can get damaged (dark screen), which would make your PSA generator uncontrollable.

Therefore, we do not recommend the application of touch panels at sites with high ambient temperatures or tropical locations just because of this particular risk. Reliability and robustness are one of the main features of our PSA nitrogen and oxygen generators.

- What is the power supply requirement?

Our generators require less then 0,3 kW at 110 or 220 Volts, 50 or 60 Hz, 1 Phase.

- What is the maintenance cost of an IGS gas generation system?

The air filter cartridges need to be replaced based on a maintenance schedule. A recommended spare parts list is supplied with every system. Annual costs vary, depending on system type, size and filter requirements. Please contact us for more details.

- I don't find my nitrogen or oxygen application on the Application pages. What should I do?

We have only mentioned the most common nitrogen and oxygen applications, but there exist many more applications of course. Based on our years of experience, we supplied our generators to almost all possible nitrogen or oxygen applications. Please contact us for the benefits of our generators for your specific nitrogen or oxygen application.

- Do you have a referral/reference list?

Yes. See also our References page.

- Is there an installation site I can visit?

We do have customers who you can visit. Please contact us to know about the nearest IGS system installed in your area.

- Do you offer installation service?

Yes. Please contact us for more details.

- Do you offer startup service?

Yes, please contact us for more details.